- Home

- Equipment

- Industries

- We Immay

- Resource

- Contact

Author: Site Editor Publish Time: 2025-10-10 Origin: Site

Shaving cream is a complex emulsion composed of water, oils, surfactants, lubricants, and moisturizing ingredients. Each of these components plays a specific role in achieving the product’s smooth texture, easy spreadability, and protective foam during shaving. However, beyond the formulation of active ingredients and emulsifiers, equal attention should be given to the quality of purified water used in production.

As the main component of shaving cream, purified water serves not only as a solvent but also as the foundation that supports the overall emulsion structure. Its purity level affects how oils and surfactants interact, influences the viscosity and consistency of the cream, and determines the product’s long-term stability. High quality purified water ensures a uniform texture, prevents unwanted chemical reactions, and contributes to a pleasant user experience.

In short, understanding and controlling water quality is a fundamental step toward producing high-performance shaving creams that meet both manufacturing and consumer expectations.

The quality of water used in shaving cream production directly affects the overall performance and appearance of the final product. Even trace levels of minerals, metal ions, or organic residues can interfere with the delicate balance of the emulsion system. These impurities may react with surfactants or fatty acids, leading to incomplete emulsification, changes in viscosity, or variations in product color and odor. Over time, such reactions can cause phase separation or a grainy texture, both of which negatively impact the consumer’s experience.

Consistent water purity ensures that every batch of shaving cream maintains the same physical and sensory characteristics. When High quality purified water is used, the viscosity and foam structure remain stable during storage, and the cream retains its smooth and uniform appearance. This stability not only enhances the product’s shelf life but also helps preserve its intended fragrance and texture over time.

Furthermore, purified water plays a key role in minimizing microbial contamination. Impurities or residual nutrients in untreated water can promote microbial growth, which increases the need for higher concentrations of preservatives. By using purified water, manufacturers can reduce this risk, allowing for milder formulations with a more skin-friendly profile. Ultimately, controlling water quality contributes to both product safety and long-term consumer satisfaction.

In shaving cream formulations, water functions as the continuous phase, providing the medium in which oils, surfactants, and other active ingredients are dispersed. This continuous phase is critical for forming a stable emulsion, as it allows oil droplets to be evenly distributed and prevents them from coalescing or separating during storage. Without High quality water, the emulsion may be weak, resulting in uneven texture, reduced foam quality, or phase separation.

The purity of water significantly influences emulsification efficiency. Impurities such as minerals or trace metals can interfere with the interaction between surfactants and oils, affecting droplet size distribution and increasing the likelihood of instability. Using purified water ensures that emulsifiers and stabilizers perform optimally, producing a smooth, homogenous cream with consistent viscosity and texture.

High quality water also plays a role in controlling the final cream’s sensory attributes. It contributes to a soft, spreadable texture and enhances the overall feel on the skin. Moreover, stable emulsions created with purified water help maintain the cream’s appearance and color, avoiding issues such as separation, opacity, or sedimentation that could occur with lower-quality water.

In addition, purified water allows formulators to develop consistent batches more easily, reducing variability between production runs and improving manufacturing efficiency. By supporting both chemical stability and physical performance, purified water becomes an indispensable component in producing shaving creams that meet quality expectations and provide a reliable user experience.

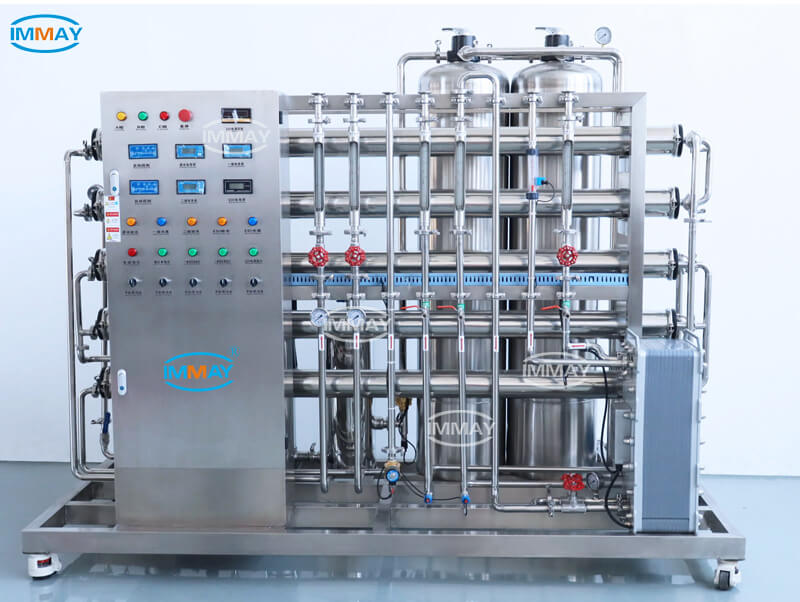

In shaving cream production, purified water is not only a key ingredient but also a critical factor in ensuring batch-to-batch consistency and product stability. Industrial reverse osmosis (RO) water purification systems are widely used to achieve this. These systems remove dissolved salts, minerals, metal ions, and organic impurities that could negatively affect emulsion stability, viscosity, or sensory attributes of the cream.

Industrial RO water treatment systems use semi-permeable membranes to separate water from dissolved solids and contaminants. Water is forced through the membrane under high pressure, leaving impurities behind. For cosmetic cream formulations such as shaving creams, 2 stage RO water treatment systems are commonly used. This configuration provides higher purity water by passing water through two RO membranes, further reducing conductivity and ion content, ensuring very low impurity levels suitable for stable, High quality emulsions.

Industrial RO purified water is used throughout key stages of shaving cream manufacturing:

Ingredient Dissolution: Dissolving hydrophilic components such as glycerin, humectants, or water-soluble preservatives.

Mixing and Emulsification: High-purity water ensures stable droplet formation and uniform emulsion structure.

Cooling and Process Support: Water quality affects temperature-sensitive reactions and maintains hygiene throughout the production line.

Stable Emulsion: Reduces the risk of phase separation and uneven texture.

Consistent Batch Quality: Minimizes variations in viscosity, color, and foam characteristics across batches.

Reduced Contamination Risk: Lowers microbial load and ensures hygienic production conditions.

Improved Process Efficiency: High quality water enhances emulsification efficiency, reduces downtime caused by product defects, and supports smooth production flow.

Industrial RO water purification systems form the backbone of reliable, High quality shaving cream production. By providing consistent, high-purity water, these systems support both the formulation stability and the overall manufacturing process, ensuring that every batch meets quality and sensory expectations.

Purified water plays a central role in shaving cream production, serving not only as a solvent but also as the foundation for a stable emulsion and consistent cream texture. Its quality directly affects viscosity, foam characteristics, and the overall sensory experience of the product.

Maintaining high-purity water throughout the manufacturing process helps ensure uniformity across batches, enhances emulsion stability, and supports the performance of surfactants and stabilizers. By carefully managing water quality, manufacturers can produce shaving creams that meet both production and consumer expectations.

For beauty manufacturers seeking reliable solutions, IMMAY provides industrial 1-stage and 2-stage RO water purification systems specifically designed for cosmetic applications, offering stable, low-impurity water that supports the consistent production of high quality shaving creams.

Contact IMMAY today to explore how our industrial pure water solutions can optimize your shaving cream production and ensure consistent product quality.