- Home

- Equipment

- Industries

- We Immay

- Resource

- Contact

1. What is a piston bottle automatic filling machine?

The piston bottle automatic filling machine is an equipment that uses the principle of a piston pump for quantitative fluid filling.

2. Filling principle of automatic piston bottle filling machine

The automatic piston bottle filling machine drives the piston to move back and forth in the material cylinder through a servo motor, and uses the suction and discharge action of the piston to control the suction and output of materials, achieving precise measurement and filling.

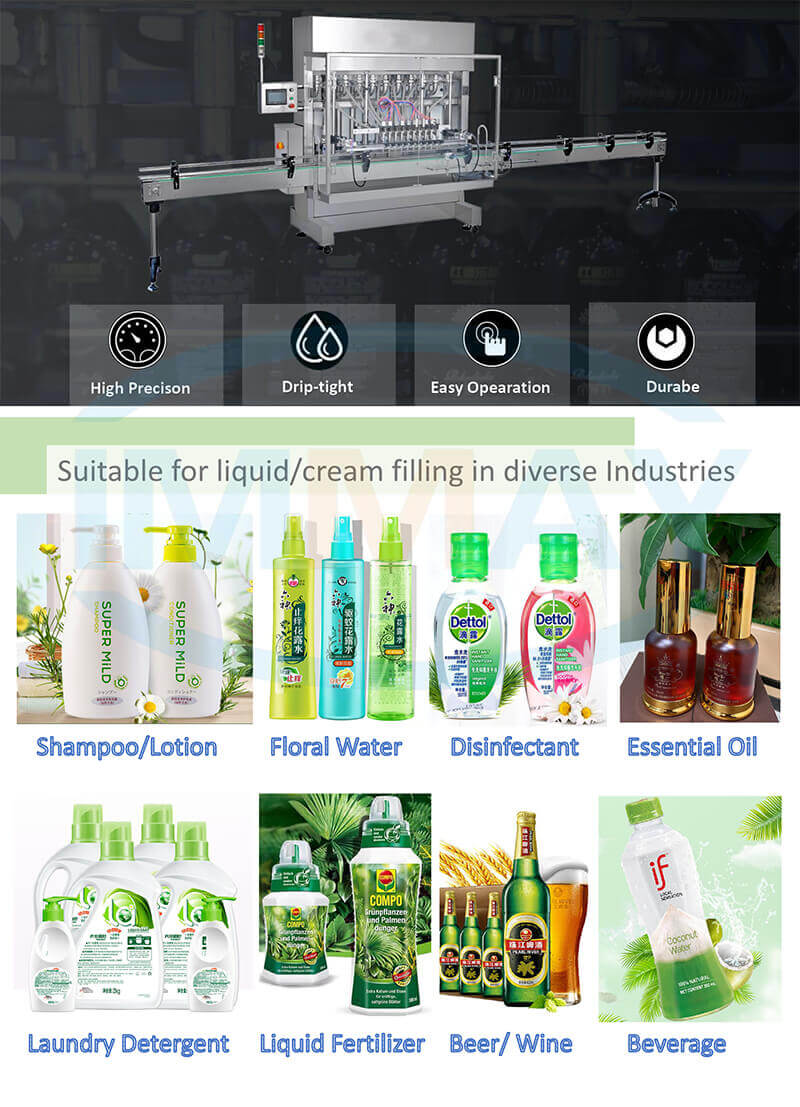

3. What materials can the automatic piston filling machine for bottles fill?

The automatic piston filling machine for bottles is widely used for filling various creams and liquid products, such as dishwashing detergent, shampoo, shower gel, hand sanitizer, sauce, seasoning, dairy products, syrup, honey, and pesticides.

4. Advantages of piston automatic bottle filling machine

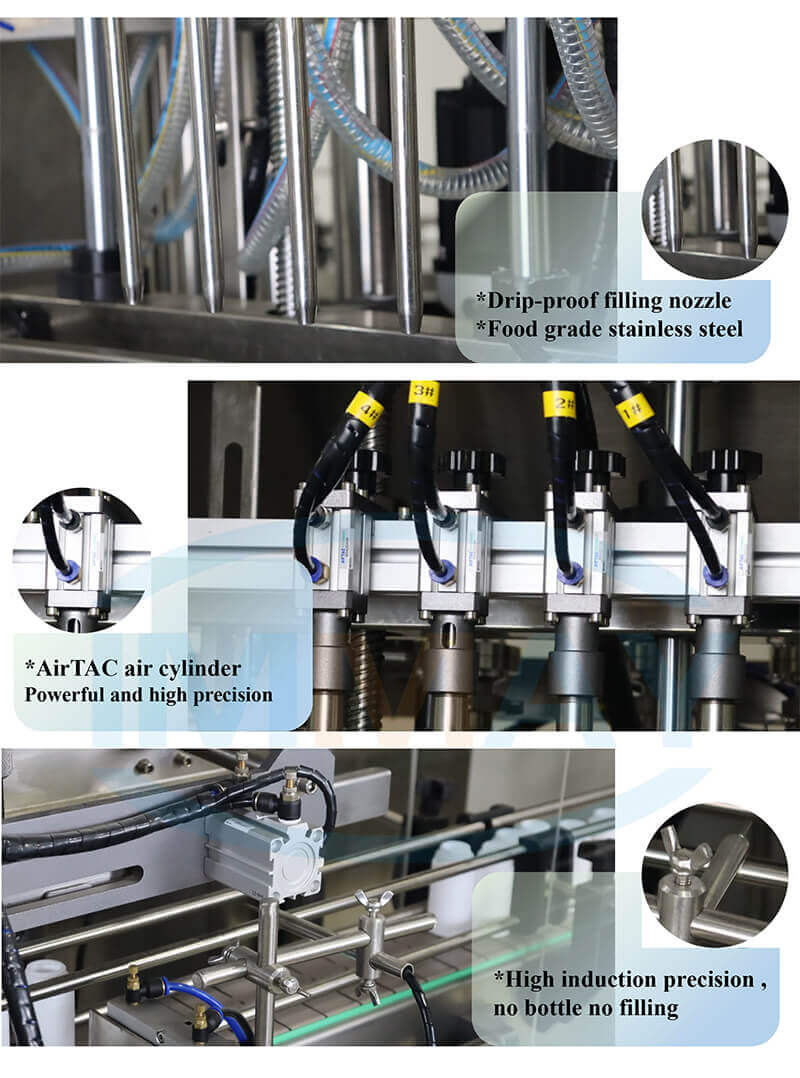

Excellent Material: The entire machine is made of stainless steel, which has excellent anti-corrosion and rust prevention properties.

Brand components: The use of well-known electrical and pneumatic components ensures the stability and low failure rate of the equipment.

High precision: Controlled by a servo system, it ensures high precision in filling.

Wide adaptability: This bottle filling machine can adapt to fluids of different viscosities, including high viscosity paste products and liquid products.

Easy to maintain: The design is simple, easy to clean and maintain, and meets GMP standards.

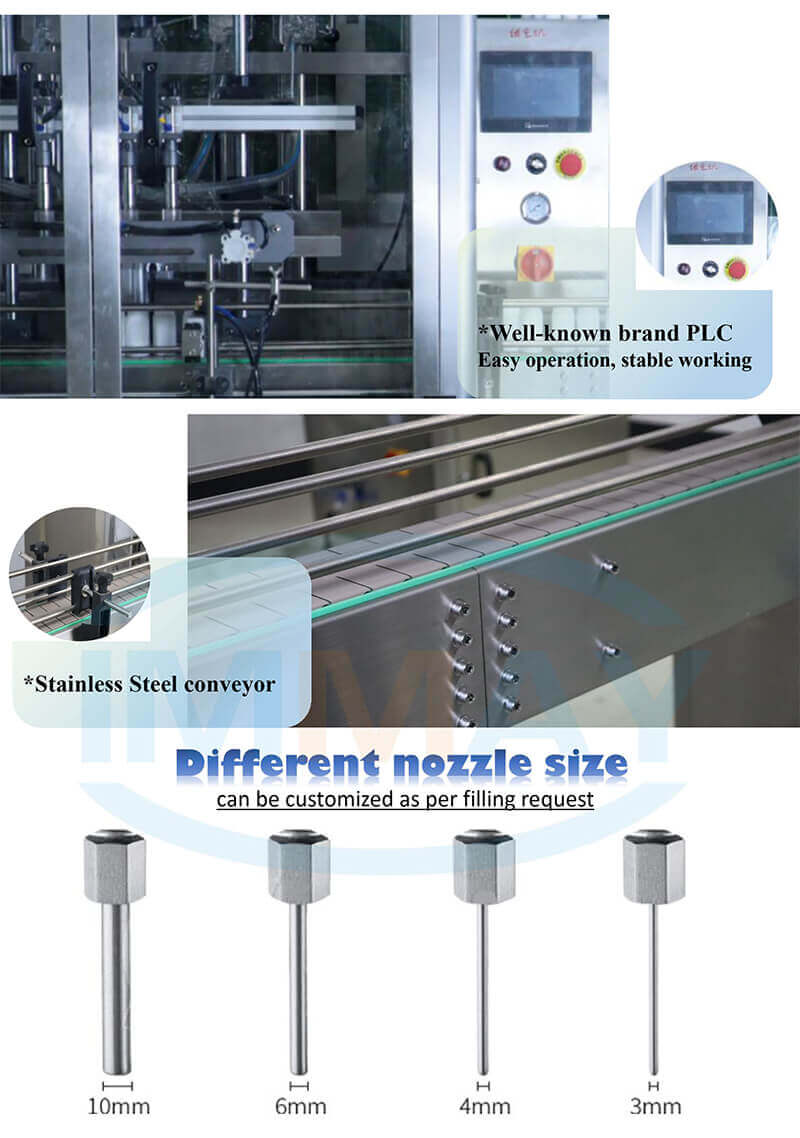

Convenient operation: Equipped with a touch screen interface, the filling speed and amount can be adjusted within a certain range according to product specifications, improving production flexibility.

Output options: 4 nozzles, 6 nozzles, 8 nozzles, and 10 nozzle piston automatic filling machines can be customized according to the output.

5. Parameters of automatic bottle piston filling machine

Model | IMA-AF2 | IMA-AF4 | IMA-AF6 | IMA-AF8 | IMA-AF10 |

Filling Range | 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 1L-5L Option | ||||

Filling speed | 25-45 bottle/min. | 30-55 bottles/min. | 40-70 bottles/min. | 60-90 bottles/min. | 80-100 bottles/min. |

Filling Accuracy | <1% | <1% | <1% | <1% | <1% |

Power | 1.5KW | 2.2KW | 4KW | 5.5KW | 7KW |

Voltage | 220V | 220V | 220V | 220V | 220V |

Working Pressure | 6-7kg/cm2 | 6-7kg/cm2 | 6-7kg/cm2 | 6-7kg/cm2 | 6-7kg/cm2 |

Weight | 400kg | 500kg | 600kg | 700kg | 800kg |

6. Main details of bottle automatic piston filling machine

Recommended Product