- Home

- Equipment

- Industries

- We Immay

- Resource

- Contact

| Availability: | |

|---|---|

What Is an Automatic Flat Bottle Labeling Machine?

An automatic flat bottle labeling machine is an industrial labeling system designed to apply self-adhesive labels onto flat or near-flat bottle surfaces in a continuous and controlled manner. It is commonly used in automated packaging lines where consistent label placement and stable operation are required.

This type of labeling machine is suitable for bottles with flat sides or gently curved surfaces that allow stable positioning during labeling. Depending on production requirements, the machine can be configured for single-side labeling or double-side labeling, ensuring accurate alignment of labels on one or both faces of the bottle.

The labeling process is automated. Bottles are conveyed, positioned, labeled, and discharged without manual intervention. Through mechanical positioning and synchronized label dispensing, the machine maintains consistent labeling results across different production batches, supporting standardized packaging operations in industrial environments.

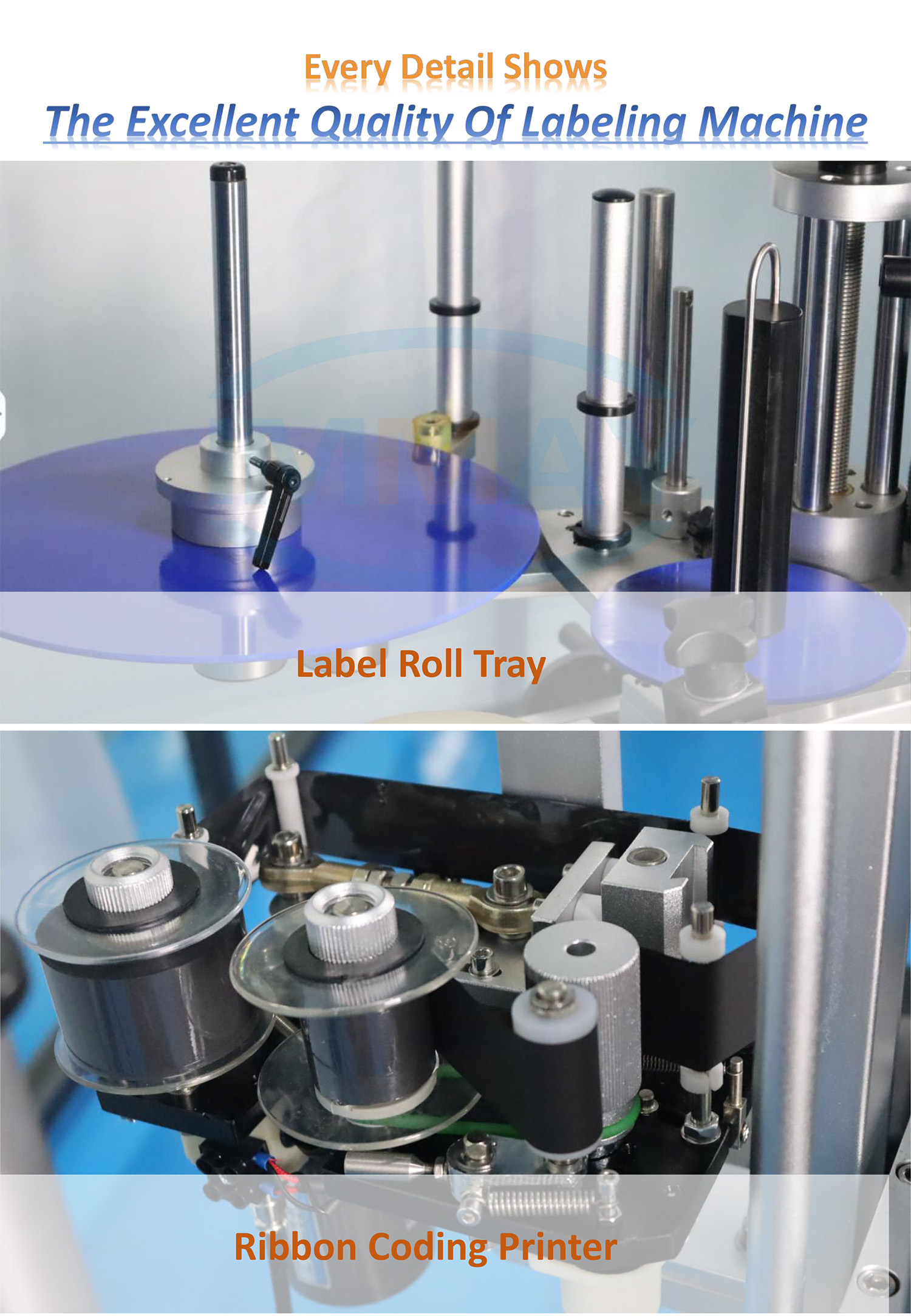

Structure of IMMAY Automatic Flat Bottle Labeling Machine

The machine consists of several key functional components designed to work together for precise and stable labeling:

Labeling Head

Responsible for dispensing and applying self-adhesive labels in synchronization with bottle movement, ensuring consistent placement on flat surfaces.

Bottle Positioning System

Guides and stabilizes bottles as they move through the labeling area, maintaining correct orientation for accurate labeling.

Conveyor System

Transports bottles through the labeling process at a controlled speed, supporting continuous operation and integration with upstream and downstream equipment.

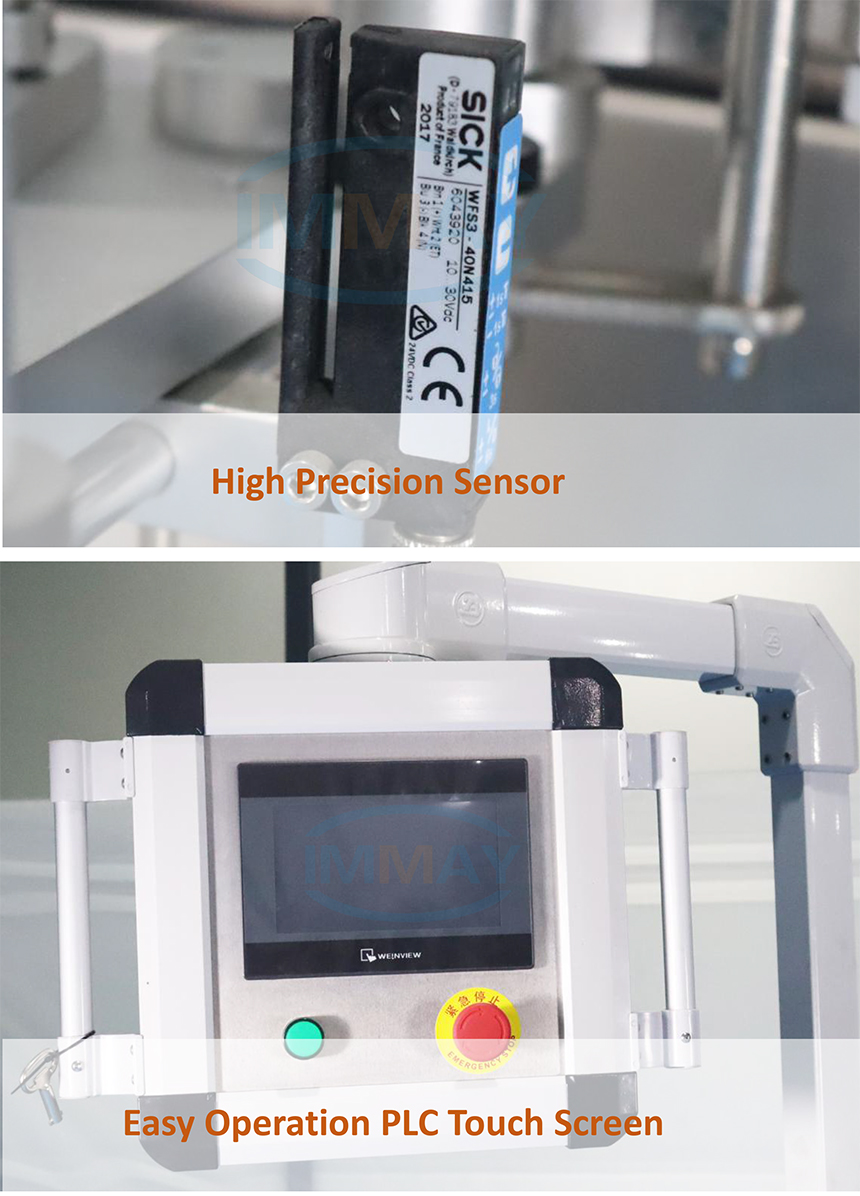

Label Sensor System

Detects label position and bottle presence to ensure precise timing and alignment throughout the labeling cycle.

Control Panel

Allows operators to manage basic operating parameters and monitor machine status, enabling straightforward control during production.

Working Principle of Automatic Flat Bottle Labeling Machine

The automatic flat bottle labeling machine operates through a continuous and coordinated labeling process designed for stable industrial production. Bottles are first fed onto the conveyor system, where they are guided and positioned to ensure consistent orientation before labeling.

Once the bottles reach the labeling station, the label dispensing system releases self-adhesive labels in synchronization with bottle movement. Label alignment is controlled to match the bottle surface, allowing precise placement on flat or near-flat areas.

As the bottles pass through the labeling zone, labels are smoothly applied onto the bottle surface through controlled contact and pressure. This process helps maintain uniform label adhesion and consistent appearance across production batches.

After labeling, the bottles continue along the conveyor and are automatically discharged for downstream packaging processes, enabling continuous operation without manual handling.

Key Features of IMMAY Automatic Flat Bottle Labeling Machine

Stable labeling accuracy for flat surfaces

The machine is designed to maintain consistent label positioning on flat and near-flat bottle surfaces, supporting uniform appearance throughout continuous production runs.

Designed for specific bottle dimensions

The labeling machine is configured according to the your bottle size and shape, with guiding and positioning structures designed to ensure stable handling of the specified container during labeling.

Smooth and consistent label application

Controlled label dispensing and application help ensure even contact between the label and bottle surface, reducing misalignment during operation.

Reliable components for long-term operation

The machine is built with industrial-grade components selected to support stable performance under routine production conditions.

Main Applications of Automatic Flat Bottle Labeling Machine

The automatic flat bottle labeling machine is suitable for a range of industrial packaging applications, with a focus on cosmetic and personal care products.

Cosmetic & Personal Care Products

Lotion bottles

Toner bottles

Shampoo and conditioner flat bottles

Skincare liquid containers

Food & Daily Chemical Products

Sauce bottles

Detergent bottles

Household liquid containers

This machine is designed to provide consistent label placement and reliable operation across production lines for these industries, supporting standardized packaging workflows.

Automatic Flat Bottle Labeling Machine for Integrated Production Lines

The automatic flat bottle labeling machine is designed to be seamlessly integrated into industrial production lines. It can operate in conjunction with:

Automatic Bottle Filling machines

Automatic Bottle Capping machines

Automatic Bottle Conveying systems

By integrating with upstream and downstream equipment, the labeling machine supports continuous operation within a standardized packaging workflow. This ensures consistent labeling performance while maintaining smooth material flow throughout the bottle packing production line.

Technical Parameters of Automatic Flat Bottle Labeling Machine

Item | Parameter |

Product Name | Automatic Flat Bottle Labeling Machine |

Labeling Accuracy | ±0.1mm |

Labeling Speed | 40-120 bottles/min. |

Bottle Diameter | Φ30mm~Φ80mm |

Label Inner Diameter | Φ76mm |

Label Outer Diameter | Max. Φ350mm |

Power | 1000W |

Voltage | 220V/50HZ (customizable) |

Dimension | 2000*800*1500mm |

Weight | 180Kg |

Main Details of Automatic Flat Bottle Labeling Machine

Recommended Products