-

Q How to choose the right Vacuum Mixer for you

A Before you start preparing for a new business, it is recommended that you choose a suitable vacuum mixer from the following aspects.

1. Production: Daily production is one of the important factors for our business success, and choosing the right production capacity is the key to choosing a suitable mixing capacity. Hydraulic Lifting Vacuum Homogenizer(10L-500L),Vacuum Emulsifying Mixer(500L-5000L)

2. Factory layout: Whether the size of the planned or existing factory can meet the layout of the machines will determine the design size of the machines.

3. Local voltage standards: Only the correct voltage can start our equipment.

-

Q Can vacuum mixers be customized for specific applications?

A Of course, we are a professional manufacturer of vacuum mixer machines. We can customize the machines according to your usage needs and production process. Our vacuum mixer customization options main include volume, heating method, control method, mixer, etc.

If you have customization needs please contact us

-

Q Advantages of IMMAY's Vacuum Emulsifier Homogenizer

A Our company is a professional production of daily chemical equipment manufacturers. With years of experience, trusted senior engineers, and machines certified to the CE standard, our line of mixing equipment is the best choice for your complex mixing process needs.

Compared with the traditional mixing equipment, vacuum emulsion mixers produced by Immay have many advantages. These benefits include:

1. Uniform mixing: Vacuum emulsion mixers provide a uniform mixture of liquid and solid to ensure consistent quality of the final product.

2. Efficient mixing: The mixer uses a high-speed homogenizer to mix raw materials, thereby achieving a faster and more efficient mixing process.

3. Reduce air bubbles: The vacuum pressure in the mixer helps remove air bubbles from the mixture, resulting in a smooth and stable product.

4. Improve product quality: The vacuum emulsion mixer improves the quality of the product by reducing the particle size of the raw material, so as to obtain better texture and consistency.

5. Hygienic design: High speed and low speed mixers are designed to meet GMP hygiene standards, making them suitable for pharmaceutical and food industries.

6. Multifunctional: Vacuum emulsifying mixers can be used in a wide range of applications, including cosmetics, pharmaceuticals, food and chemicals.

7. Easy to clean: Mixers are easy to clean and maintain, which reduces downtime and increases productivity.

The vacuum emulsion mixer produced by Immay is an efficient and versatile mixing device that can offer a range of benefits to manufacturers in a wide range of industries.

-

Q Vacuum mixer price range of Immay

A Immay specializes in providing customized vacuum mixers for you. The equipment prices will vary according to your requirements before you plan to buy, usually ranging from thousands of dollars to tens of thousands of dollars. We always adhere to the principle that machines are priced and services are priceless, providing you with a pleasant user experience has always been our Immay original intention.

-

Q How to choose a suitable reverse osmosis water treatment equipment?

A If you are unsure about which water treatment equipment is suitable for you, you can typically make a choice from the following three perspectives. 1. Purpose of pure water

What is your purpose of purchasing water treatment equipment?

According to the use, there are mainly two uses: raw material water for production and non-process water:

(1) If it is water used for raw materials, then you need to tell us what kind of products you plan to make. Usually, the products that can be applied to primary reverse osmosis equipment mainly include detergents, cleaning agents, pesticides, liquid fertilizers, etc. The secondary reverse osmosis equipment is more widely used than the primary reverse osmosis equipment, mainly including cosmetics, beverages, daily necessities, skin care products, food, semiconductors and other products, but in some special application scenarios, the requirements for water quality are higher. For example, products such as potions and perfumes not only need to be processed by the secondary reverse osmosis water treatment machine, but also need to be processed by the distillation process to meet the needs of use;

(2) If it is non-process water, then in daily application, we mainly use source water to produce drinking pure water and mineral water. Drinking pure water can use secondary reverse osmosis water treatment equipment, while mineral water can use primary reverse osmosis water treatment equipment. Permeate water treatment equipment or use ultrafiltration water treatment equipment.

2. Raw water quality

The quality of raw water plays a vital role in the selection of water treatment equipment. Usually, the source water we can obtain mainly includes surface water and groundwater, including river water, river water, lake water, stream water, and reservoir water. Water, because the surface water flows on the ground, the dissolved minerals are less, and the water quality is soft. The hardness of this type of water is usually 0.5~4.0mmo1/L. Surface water is easily polluted, and some rivers, lakes and streams actually contain part of groundwater, so in addition to sediment and organic matter, there are also a variety of soluble salts. Well water and spring water belong to groundwater, and groundwater can be divided into shallow groundwater and deep groundwater. Shallow groundwater has better physical properties and clear water quality, but it often dissolves certain mineral salts in the soil, making the water hard; deep groundwater has better quality than shallow groundwater, but if there are some salts in the water layer When used, it can also harden the water, making it unsuitable for drinking and use. The hardness of groundwater is generally 1.0~5.0mmo1/L, and some are as high as 5.0~12.5mmo1/L. Usually surface water with low hardness can be treated with quartz sand and activated carbon, but groundwater and surface water mixed with groundwater need to be softened by resin and medicine box in the treatment of quartz sand and activated carbon before further reverse osmosis filtration deal with. Of course, in some special applications, in order to obtain better water quality, we can also perform ozone sterilization, UV sterilization, distillation and other processes.

3. Daily output

Daily output is also one of the important factors in choosing reverse osmosis water treatment. How many tons of pure water your factory needs every day and how long your factory runs are important information. The specifications of water treatment equipment provided by Immay mainly include 500L /H, 1000L/H, 1500L/H, 2000L/H, 2500L/H, 3000L/H, 5000L/H (1 US gallon=3.7854118 liters), etc., you can choose the appropriate output according to your actual needs to match your Daily production plan.

-

Q Advantages of reverse osmosis technology

A Reverse osmosis (RO) water filtration technology, powered by pressure difference, stands as the most advanced, energy-saving, and effective membrane separation technology today. (1) Efficient removal of impurities: the reverse osmosis membrane can efficiently remove impurities such as ions, dissolved substances, organic matter and microorganisms in water, making the water produced extremely pure. This high efficiency makes reverse osmosis technology the method of choice for industrial and commercial production of high-purity water;

(2) Energy saving and environmental protection: Compared with traditional water treatment methods, reverse osmosis technology has the characteristics of low energy consumption and no need to add any chemical reagents, and will not produce secondary pollution, so it is more environmentally friendly;

(3) Wide range of application: reverse osmosis technology can treat various types of water sources, including tap water, lake water, river water, sea water and other water sources, and can be flexibly adjusted according to different water quality requirements, so the application range is very wide;

(4) Easy to operate: Compared with other pure water equipment, the operation of reverse osmosis technology is very simple. Only some basic equipment and operation steps are needed to treat the water source into high-purity water, without much professional knowledge and skills.

-

Q Composition of RO water treatment system

A Reverse osmosis water treatment technology is a relatively popular water treatment technology at present. With this technology, impurities in water can be effectively removed and high-quality, high-purity water can be obtained, which is more and more popular among people. The reverse osmosis device is the core equipment to realize the reverse osmosis technology, and its composition and structural principles are the key to realize its efficient and reliable operation.

(1) The pretreatment system generally includes raw water pump, quartz sand filter, activated carbon filter, softening and dosing device, precision security filter, etc. Its main function is to reduce the pollution index of raw water and other impurities such as residual chlorine, so as to meet the water inlet requirements of reverse osmosis. The equipment configuration of the pretreatment system should be determined according to the specific conditions of the raw water.

(2) The reverse osmosis system mainly includes multi-stage high-pressure pumps, reverse osmosis membrane elements, membrane shells (pressure vessels), supports, etc. Its main function is to further remove small impurities in the water, so that the quality of the effluent water can meet the requirements of use.

(3) The ultrapure water system is an additional configuration when the water quality of the reverse osmosis effluent cannot meet the quality of the water used. It mainly includes one or more equipments such as EDI and mixed bed. The ultrapure water system is based on reverse osmosis to further remove ions to meet the requirements of use.

(4) The electrical control system is used to control the normal operation of the entire reverse osmosis system. Including instruments, control panels, various electrical protection, electrical control cabinets, etc.

-

Q Functions of each component of reverse osmosis water treatment filter

A (1) Quartz sand filter:

the British sand filter is made of fine quartz sand filter materials filled with different specifications in the filter. The colloidal particles are intercepted, thereby reducing the turbidity of the water. Users can choose to use it according to the actual situation. The filtration accuracy is between 0.005-0.01m, which can effectively remove colloidal particles and high-molecular organic matter.

(2) Activated carbon filter:

The main function of activated carbon filter is to remove organic substances in water, including trace organic substances such as odor, color, and lubricating oil. These organic substances will have a great impact on the quality and use effect of water. Through the treatment of activated carbon filter, these organic substances can be removed to improve the quality and use effect of water. Usually we use granular coconut shell activated carbon as the filter medium. Granular coconut shell activated carbon is not easy to flow because of its particle shape, and impurities such as organic matter in water are not easy to block in the activated carbon filter layer, and has strong adsorption capacity, so it is widely used.

(3) Precision security filter:

The security filter is mainly a filter with PP melt-blown filter element as the filter element. It is the last filtration system before entering the reverse osmosis membrane. The filtration accuracy is 5 microns. It can effectively remove the particles and colloidal substances, and can effectively retain the particulate matter directly larger than 5 microns in the water after the treatment of the sand and carbon filtration system, so as to ensure the cleanliness of the water entering the RO membrane. The main purpose is to effectively protect the reverse osmosis. The membrane will not be clogged and scratched prematurely, thereby prolonging the service life of the RO membrane in the reverse osmosis system.

(4) Reverse osmosis membrane:

reverse osmosis membrane filtration is a physical filtration technology. The surface separation pore size of the reverse osmosis membrane is below 0.001um, which is as small as nanometers, and can separate ions. Since the pore size of the RO membrane is one millionth of a hair The fifth (0.0001 micron) is generally invisible to the naked eye. Bacteria and viruses are 5000 times larger than it. Reverse osmosis is a filtration technology that uses osmotic pressure difference as the driving force. Under a certain pressure, water molecules in source water can pass through the RO membrane. , while inorganic salts, heavy metal ions, organic matter, colloids, bacteria, viruses and other impurities cannot pass through the RO membrane, so that the permeable pure water and the impermeable concentrated water are separated and the purest pure water is obtained. Usually, tap water is used as source water. When tap water is filtered by RO membrane, the conductivity of pure water is between 5μs/cm~10μs/cm, and the desalination rate can reach more than 98%. Therefore, the reverse osmosis RO membrane has been widely used in the water purification industry and industrial production water.

(5) Continuous electric desalination technology:

Continuous electric desalination technology, also known as EDI, is a combination of traditional electrodialysis technology and ion exchange technology. Sexual action and the ion exchange effect of the ion exchange resin on the ions in the water, so that the ions in the water move in a directional manner, so as to realize the deep purification and desalination of the water. The hydrogen ions and hydroxide ions generated by water electrolysis continuously regenerate the resin, so the water production process of the EDI module does not require acid-base chemical regeneration to continuously produce high-quality ultrapure water. The EDI module is a continuous water purification process, so the water quality of its products is stable. After EDI technology treatment, the conductivity of the water can be reduced to 0.1-1.0μS/cm, reaching the standard of ultra-pure water.

(6) Pure water tank:

The main function of the pure water tank is to store filtered pure water. The main materials of the pure water tank are plastic and stainless steel. The use of the pure water tank can reduce the frequent start and stop of the reverse osmosis water treatment equipment, which can effectively increase the The service life of reverse osmosis water treatment equipment.

-

Q How long can industrial and commercial reverse osmosis water treatment equipment last?

A While industrial and commercial reverse osmosis water treatment systems are powerful and work well, their filter elements don't last forever. These elements require some routine maintenance on your part each year to keep them functioning properly. Otherwise, the water filtered by the reverse osmosis water treatment equipment will not meet your requirements.

When functioning properly, the reverse osmosis filtration process has at least three, but sometimes perhaps four distinct stages: quartz sand filter, activated carbon filter, precision security filter, and then the reverse osmosis membrane filter. In order to obtain a continuous supply of high quality pure water, each of the different filter elements requires periodic replacement. How long these filters last usually depends on your usage factors and the quality of your source water. Under normal circumstances, reverse osmosis membranes can be used for 1 to 5 years. Other filters, however, require replacement more quickly. Typically the pre-filter elements of a reverse osmosis water treatment system can last anywhere from six months to a year. A good experience is that you regularly check the equipment operation status.

-

Q Price range of industrial and commercial reverse osmosis water treatment equipment

A The price of a 1 stage or 2 stages reverse osmosis (RO) water treatment equipment depends on many factors. As we discussed above, source water quality, pure water output and materials are all important factors affecting the price. Generally, reverse osmosis water The price of processing machines ranges from thousands of dollars to tens of thousands of dollars, you can contact us for free to get the latest price.

-

Q Daily maintenance of RO water treatment plant

A The maintenance of reverse osmosis pure water equipment includes equipment cleaning and maintenance, the main purpose is to prolong the service life of the equipment and improve product quality.

(1) Regularly check the raw water quality and flow rate, and adjust the operating parameters of the machine in time according to the changes in the raw water quality to ensure that the water produced by the reverse osmosis water treatment equipment is stable and reliable.

(2) Regularly check the working conditions of the main components, such as whether the precision security filter, reverse osmosis membrane, etc. are in normal operation.

(3) Regularly clean and replace the components in the filter devices such as quartz sand filters, activated carbon filters and precision security filters.

(4) Clean the pure water tank regularly to ensure the hygiene and quality of pure water.

(5) In low-temperature areas, it is necessary to do a good job of insulating the pipeline in winter to prevent the water from freezing and causing damage to the operation of the equipment.

(6) After the equipment is used every day, the stains on the outer surface of the equipment should be cleaned in time to extend the service life of the equipment.

-

Q The classification of liquid or cream mixing machine

A IMMAY's liquid or cream mixing machines are mainly divided into two categories: liquid or cream mixing tanks and liquid or cream mixing machines. These two types of liquid or cream mixing equipment have their own characteristics in terms of functions and application.

Liquid or cream mixing tanks are common liquid or cream mixing equipments primarily used for mixing and storing fluid products. IMMAY's liquid or cream mixing tanks are made of high quality stainless steel. Their structure mainly includes a tank body, agitation device, heating or cooling system, and control system. The design of IMMAY's stainless steel liquid or cream mixing tank ensures uniform mixing of the liquid or cream inside the tank to achieve the desired mixing effect. This mixing equipment is suitable for mixing liquid-powder-granule raw materials and can be used in various industries such as cosmetics, pharmaceuticals, food, and chemicals for mixing multiple raw materials. IMMAY's stainless steel liquid or cream mixing tanks are characterized by high efficiency mixing performance, stable operation, and ease of operation, and can meet the needs of different production scales.

Liquid or cream mixing machines are industrial mixing machines developed for small businesses and workshops. They can achieve rapid and uniform mixing effects. IMMAY's liquid or cream mixing machines employ advanced mixing technologies, including high speed dispersion and high shear homogenization, and can handle liquid and creams of various viscosities and properties. The high speed disperser can quickly distribute particles or ingredients in the liquid or cream uniformly, while the high shear homogenizer can thoroughly mix liquid and creams of different viscosities, ensuring that the mixed liquid or cream has good stability and uniformity. IMMAY's liquid or cream mixing machines have high mixing efficiency and precise control capabilities and are suitable for production processes with high mixing quality requirements.

-

Q How does a liquid or cream mixing machine work?

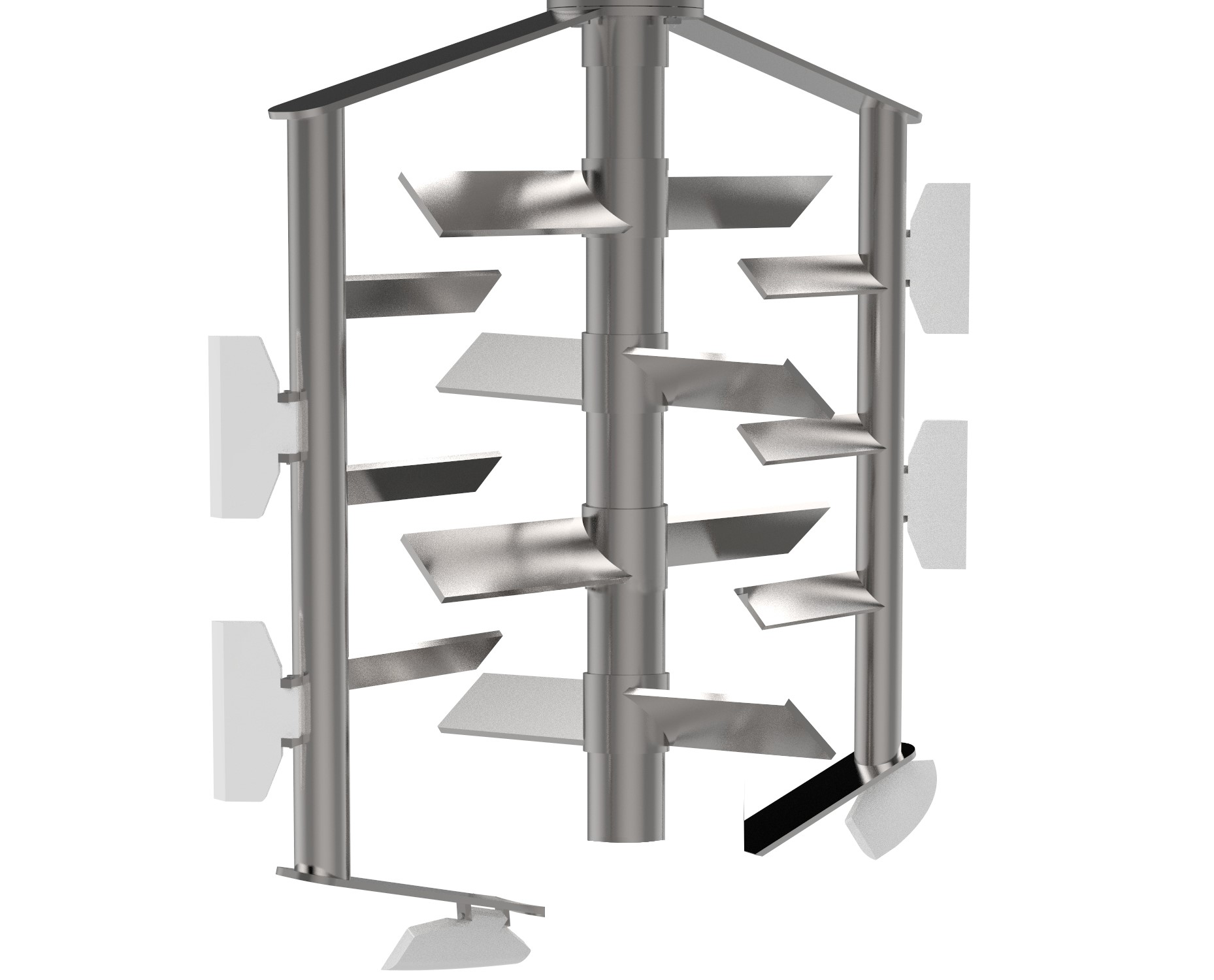

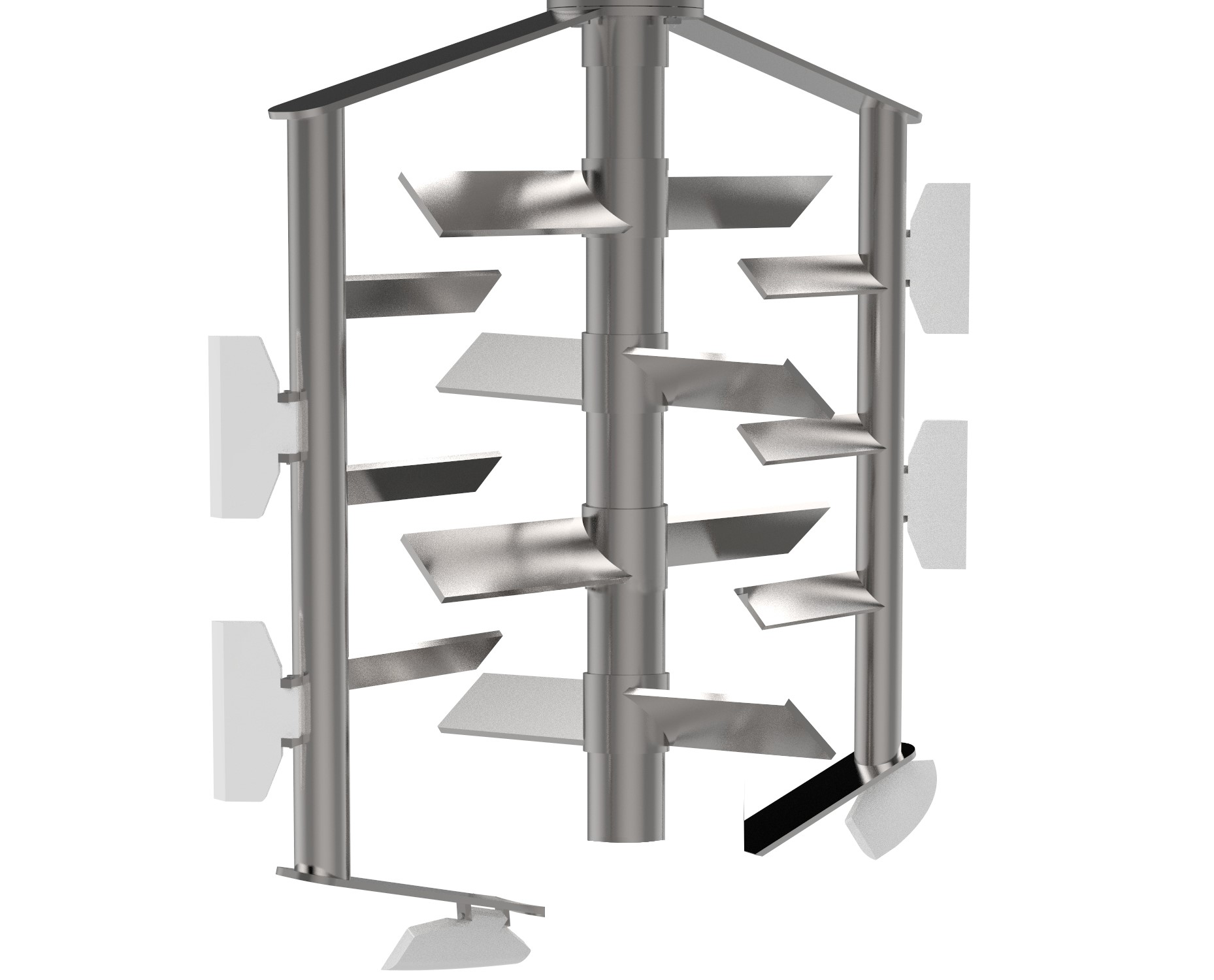

A The liquid or cream mixing machine is composed of motor, reducer, bearing, swing shaft, agitator and other components. The motor is driven by a reducer to make the swing shaft rotate, and the swing shaft drives the stirrer to rotate, thereby forming a strong stirring energy to mix liquid-powder-particle together. The impeller of the agitator adopts a special design, which can circulate the material in multiple dimensions, and use the rotational kinetic energy of the swing shaft to quickly and evenly mix the liquid and the solid.

In addition, the mixer can also achieve different mixing effects by controlling the rotation speed of the swing shaft. Generally speaking, the faster the rotation speed of the swing shaft, the better the mixing effect and the finer the mixture; the slower the rotation speed of the swing shaft, the worse the stirring effect and the coarser the mixture.

-

Q What are the different types of industrial agitators?

A In liquid or cream mixing machines, the role of the agitator is very important. It is the key factor for effective liquid or cream mixing. Choosing a suitable agitator will help us obtain high quality products in a short period of time. Next, Immay will present 4 types of agitators that are widely used in daily use.

1. Three-blade agitator

Three-bladed impellers are often used for mixing low viscosity fluids. When stirring, the fluid is sucked in from the top of the paddle, and discharged in a cylindrical spiral form from the bottom. The fluid reaches the bottom of the container and then returns to the top of the paddle along the wall, forming an axial flow. The degree of turbulence of the fluid is not high during stirring, but the circulation volume is large.

The diameter of the three-lobe blade is usually small, but the mixing speed is fast, and it is easy to manufacture. It is suitable for the application scene with low viscosity and large flow rate. The liquid dispersion mixer can use the low stirring power to obtain better mixing effect through the three-lobe blade rotating at high speed. Although the circulation performance of the three-blade stirring paddle is good, its shearing effect is not large. It belongs to the circulation type stirring paddle. It is mainly used for uniform mixing of liquid-liquid, liquid-powder and liquid-particle system products in the industries of medicine, food, chemical industry and cosmetics.

2. Dispersion disc agitator

Dispersing discs are mainly used for crushing, stirring and grinding of liquid, emulsion and liquid- partic le products in paint, pigment, dye, paint, ink, adhesive, food, medicine, daily chemical and other industries.

The dispersing disc is connected to the main shaft of the high speed dispersing machine. When the main shaft of the disperser is running at high speed, the top and bottom of the dispersing disc are in a rotating state, and at the same time, a turbulent zone will be formed at the edge of 2.5-5mm. The upper and lower serrations of the dispersing plate perform high-speed shearing, impacting, crushing and dispersing of coatings, paints, dry powder, liquid- partic le and other materials, so as to achieve the state of rapid mixing, dissolution, dispersion and refinement.

Advantages of dispersing disc - High strength, strong and durable.

- The specifications can be flexibly adjusted according to the power of the disperser, which is simple and practical.

- Easy to replace, easier to clean, and pollution-free.

3.3 Frame agitator

There are two types of frame impellers: straight blades and folded blades. The blade surface of the straight blade is perpendicular to the direction of rotation, while the blade surface of the folded blade forms an oblique angle with the direction of rotation. The straight paddle mainly makes the material flow in the tangential direction, and the folded paddle can not only make the material do circular motion, but also make the material move up and down, which is more sufficient than the straight stirring effect. Under the same power, because the power consumption of the axial flow blade is less than that of the radial flow blade, the folded leaf frame type impeller is used more.

According to the mixing process and the volume of the container, the frame-type impeller can be designed with single-layer, double-layer or multi-layer blades. The frame-type impeller can make the stirring medium flow in the axial, radial and circumferential directions at the same time, so that it can reach a certain stirring intensity in a short period of time, meet the requirements of uniform and sufficient mixing, and have low hydraulic loss. It is widely used in the uniform mixing of high-viscosity products in food, medicine, cosmetics, and chemical industries.

4 Homogenizer agitator

The high shear homogenizer mixer is a set of precision stainless steel stator-rotor system. Due to the high tangential velocity generated by the high-speed rotation of the rotor and the strong kinetic energy brought by high-frequency mechanical effects, the material is subjected to strong mechanical and hydraulic shearing, centrifugal extrusion, liquid layer friction, impact tearing and other comprehensive effects in the narrow gap between the stator and the rotor to form suspoemulsions, emulsions and foams. So that the immiscible solid phase, liquid phase, and gas phase are uniformly and finely dispersed and emulsified in an instant under the combined action of corresponding mature technology and appropriate amount of additives. After high-frequency cycles, stable high quality products are finally obtained.

The high shear homogenizer has a large batch processing capacity and is suitable for industrial continuous production. It can be widely used in the large-scale production of mayonnaise, lipstick, ointment, paint, pesticides and other products in the food, pharmaceutical, cosmetic, chemical and other industries

-

Q How to choose the right liquid or cream mixing machine for you

A If you are struggling to choose a suitable liquid or cream mixer, we recommend that you consider the following four dimensions based on your production needs:

Mixing capacity

Corrosion resistance requirements

Process requirements

Hygiene requirements

1. Mixing capacity

① Mixing Tank With Agitator can also be called a liquid or cream mixing tank, with a volume of 50-5000L.

Usually, if the capacity is less than 500L, a mobile caster design can be used instead of a platform to facilitate movement.If the capacity is greater than 500L, one or more continuous platforms can be used, which can achieve large-scale industrial assembly line production.

② Movable-lifting-homogenizer-mixer without a stirring container can also be called a mobile mixer (including low-speed mixer, high-speed disperser, and high shear homogenizer). The conventional mixing volume is less than 500L.

2. Corrosion resistance requirements

The corrosion resistance levels for liquid mixers are categorized as low, medium, and high. The available materials include carbon steel liquid or cream mixers, stainless steel liquid or cream mixers, and PP (polypropylene) liquid or cream mixers, respectively.

① Stainless steel is a metallic material with excellent corrosion resistance. It can be used for a long time in acidic media such as sulfuric acid, hydrochloric acid, nitric acid, and hydrofluoric acid with a concentration of less than 50%. In addition, stainless steel also has good wear resistance and high temperature resistance, so it is widely used in chemical, pharmaceutical, food and other industries.

② PP (polypropylene) is a thermoplastic with excellent acid resistance. It can be used for a long time in acidic media such as sulfuric acid, hydrochloric acid, nitric acid, and hydrofluoric acid with a concentration of less than 90%. In addition, polypropylene also has good corrosion resistance, wear resistance and high temperature resistance, so it is widely used in chemical and other industries.

3. Process requirements

If the product adopts the cold mixing process, there is no need for heating and cooling during the mixing process, and a single-layer liquid or cream mixing machine can be used. If the product adopts the hot mixing process, heating and cooling are required during the mixing process, so a three-layer liquid or cream mixing machine is required for mixing. According to the needs of heating sources, we can provide electric heating three-layer liquid mixing machines and steam heating three-layer liquid or cream mixing machines.

4. Hygiene requirements

According to hygiene requirements, it can be divided into open lid liquid or cream mixing machine and sealed liquid or cream mixing machine. In the food, medicine, and cosmetics industries, hygiene requirements are usually relatively high. We can use sealed liquid or cream mixing machines to produce products. Sealed liquid or cream mixing machines can effectively prevent dust and bacteria from entering the tank to pollute products. However, in the chemical industry, due to the low hygiene requirements for chemical products, We can use open lid liquid or cream mixing machines for production. -

Q What are liquid or cream mixing machine prices?

A There are many factors that affect the price of liquid or cream mixing equipments before we plan to buy, such as whether we are a large-scale production line or a small business, and the performance requirements of the mixing machines (capacity, horsepower, heating method, etc.). You can inquiry Immay for free, and we will provide you with a unique solution according to your needs.

-

Q Operation process of liquid or cream mixing machine

A - Preparations:Before starting the machine, check whether the appearance of all parts of the liquid or cream mixing machine is normal, whether there are foreign matters in the tank, and whether the machine is well grounded.

- Adding materials: According to the process requirements, gradually add the materials that need to be stirred into the liquid or cream mixing tank, paying attention to the amount and order of materials added.

- Start the liquid or cream mixing machine: Press the start switch, and the mixer starts to rotate and mix.

- Mixing: Mix, disperse, and homogenize materials in a liquid or cream mixing machine to achieve a fully uniform mixing effect.

- Stop mixing: After mixing is completed, press the stop switch to turn off the mixer.

- Discharge: Open the discharge valve located at the bottom of the liquid or cream mixing tank and empty the material inside the tank through the connected pipeline.

- Cleaning: Use clean water to clean the residual materials inside the mixing tank and keep the mixer clean and hygienic.

-

Q Daily maintenance of liquid or cream mixing machine

A How do I maintain and clean a liquid or cream mixing machine? IMMAY are willing to share your some tips from the following points.

Regular maintenance: Regularly inspect the liquid or cream mixer machine, replace consumables such as cooling water and lubricating oil, and ensure the normal operation of the machine.

Pay attention to cleaning: After using the liquid or cream mixer machine every day, it should be cleaned in a timely manner to avoid material residue on the body and long-ter m pollution and corrosion of machine components.

Timely maintenance: Once a malfunction or abnormal situation is found in the liquid or cream mixer machine, it should be repaired and handled in a timely manner to avoid the probl em from expanding.

-

Q 1. Emulsion Stability

A Issue: The emulsifier needs to generate sufficient shear force to break down oil droplets and disperse them evenly in the aqueous phase. Insufficient shear force may lead to incomplete emulsification, potentially resulting in product stratification or poor stability.

Immay’s solution: Immay ensures sufficient shear force by continuously upgrading and optimizing the homogenizing head of the emulsifier.

Operators can adjust emulsification speed and time according to actual conditions to achieve optimal emulsification effects.

Using high-quality emulsifiers, such as lecithin, to enhance emulsion stability.

-

Q 2. Temperature Control

A Issue: Temperature control is crucial during emulsification. Excessive temperatures will damage the protein structure in egg yolks, affecting emulsification effectiveness and the final product's texture. Additionally, temperature fluctuations can lead to product spoilage.

Immay’s solution: Immay's industrial mayonnaise mixer features cooling or heating systems that can adjust the temperature inside the mixing tank according to mayonnaise formula process request.